Content content

Climate change and environmental issues are no longer optional challenges; they are essential problems that must be solved. As the need for green transformation across industries intensifies, the importance of sustainable materials and chemical technologies is greater than ever. Following the innovative solutions shown by Hyosung TNC and Hyosung Heavy Industries in Part 1, this second part explores how Hyosung Advanced Materials and Hyosung Chemical are shaping a sustainable future with their technologies and products.

HS Hyosung Advanced Materials - Material Innovation Minimizing Harmful Elements

HS Hyosung Advanced Materials is a global company that produces high-strength industrial yarns, fabrics, and wire materials based on proprietary technologies. With rising awareness of environmental issues, customers are increasingly demanding the reuse and recycling of fossil-fuel-based products, as well as a shift toward bio-based raw materials. In response to these market changes, HS Hyosung Advanced Materials is promoting various green management strategies, such as developing technologies and products that improve energy efficiency and using resources that help protect ecosystems.

HS Hyosung Advanced Materials' TANSOME® is an innovative carbon fiber developed using Korea's first proprietary technology. It is an advanced material with exceptional properties, being four times lighter and more than ten times stronger than steel. Thanks to these characteristics, TANSOME® is highly effective for product lightweighting, making it a key material for automotive applications, where it enhances fuel efficiency and reduces carbon emissions. Also, recognized for its outstanding stability and functionality, TANSOME® is widely used across various industries, including automotive, aerospace, sports equipment, and sustainable energy sectors such as CNG and hydrogen high-pressure containers.

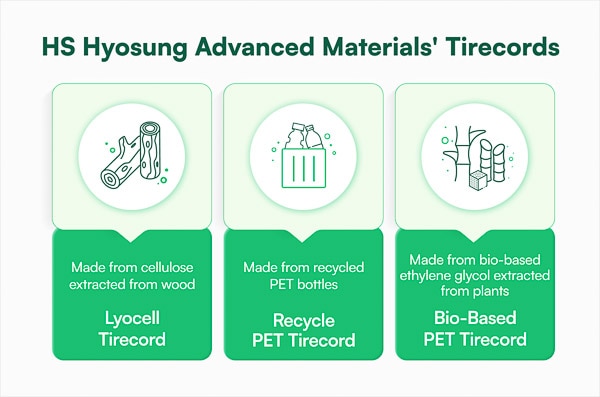

Tirecords are reinforcement materials inserted into tires to enhance durability during high-speed driving. Rayon, commonly used as a reinforcement material for high-speed tires, has posed environmental concerns due to the generation of harmful substances during its production, which involves the use of sulfuric acid. To address this issue, HS Hyosung Advanced Materials developed the Lyocell Tirecord, which uses cellulose extracted from wood as its raw material. Made from natural wood-based raw materials, Lyocell Tirecord significantly reduces the emission of harmful substances during production and is 100% biodegradable, realizing sustainable technology.

HS Hyosung Advanced Materials has been committed to minimizing environmental impact. Since 2020, the company has developed and commercialized Recycle PET Tirecord products made from recycled PET bottles. Recycle PET is not only used for tirecords but also for tire yarn (TY) and interior design materials, demonstrating the versatile application of this recycled materials. Additionally, the company has developed Bio PET yarn made from bio-based ethylene glycol derived from plants like sugarcane and corn, which reduces environmental impact compared to conventional products.

Hyosung's technological advancements have been validated through recognized eco-certifications, ensuring the objectivity and transparency of its products. In 2022, the company’s tirecords and TY production processes, which utilize bio-based PET, earned and maintained the prestigious ISCC PLUS certification. Additionally, its industrial yarn products made from recycled materials achieved GRS certification. These milestones have laid a foundation for HS Hyosung Advanced Materials to expand the sale of products that reduce environmental impact. The company has also set a goal to transition the raw materials for its signature products, such as tire reinforcements and industrial yarns, to sustainable alternatives.

Hyosung Chemical: Driving Carbon Reduction through Chemical Innovation

Hyosung Chemical specializes in producing polypropylene (PP), films, and other chemical products while acknowledging their environmental impact. The company is actively developing low-carbon and bio-based products and commercializing recycled plastic materials to reduce environmental burdens. At the same time, these efforts are complemented by its pursuit of innovative technologies for future growth.

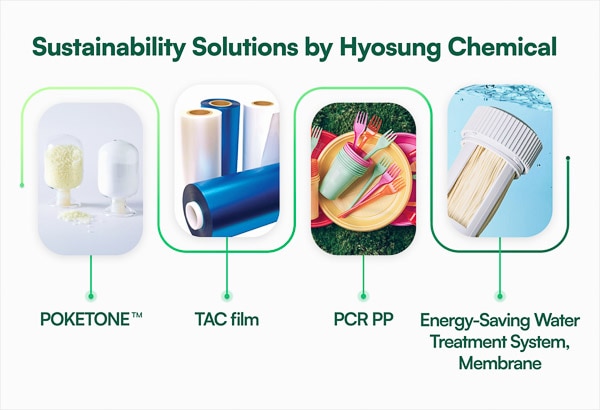

One standout innovation is POKETONE™, a proprietary low-carbon, high-performance engineering plastic. Developed using Hyosung Chemical’s independent technology, POKETONE™ boasts exceptional strength and chemical resistance, making it a viable alternative to metals. It has a significantly smaller carbon footprint compared to other engineering plastics such as polyamide (PA) and polybutylene terephthalate (PBT). Its manufacturing process has been recognized with Green Technology Certification from the Ministry of Trade, Industry, and Energy (MOTIE). These advantages make POKETONE™ a versatile material, widely used in various fields such as automotive, electronics, and consumer goods.

Hyosung Chemical successfully became the first in Korea to independently develop TAC (Tri-Acetyl Cellulose) Film, widely used in LCD displays and other applications. The primary material for TAC film is Cotton Linter, a type of biomass, making it not only sustainable but also compliant with regulations on hazardous substances. The film boasts high quality and meets the stringent standards of the USDA's BioPreferred® program, achieving a biomass content of 47%, surpassing the minimum requirement of 45% for the "Films: Semi-Durable" category. Moving forward, Hyosung Chemical plans to increase the biomass proportion in its TAC films, ensuring compliance with global environmental regulations and solidifying its position in the market as a leader in sustainable innovation.

Hyosung Chemical has recently established a new PCR (Post-Consumer Recycled) PP business. PCR materials are plastic compounds made by recycling waste plastics. In collaboration with the Korea Marine Environment Management Corporation and the Korea Tugbusiness Corporation, the company is collecting discarded ropes from tugboats. These ropes, combined with post-consumer waste materials like PP and PE, are processed into PCR-PP pellets. This initiative promotes resource circulation and helps address the issue of marine waste.

Hyosung Chemical also contributes to clean water supply and environmental protection through advanced energy-saving water treatment technologies. Starting with the "submerged water treatment technology" and progressing to "pressurized membrane filtration systems," the company has secured certifications for environmental innovations. The submerged system maximizes purification efficiency by removing impurities through immersed membranes and operates effectively in diverse water conditions. The pressurized filtration system offers a high-performance solution to enhance water quality by eliminating even microscopic contaminants using high-pressure filtration.

Through these efforts, including the development of low-carbon products, use of recycled materials, and cutting-edge water treatment technologies, Hyosung Chemical is dedicated to environmental protection and fostering a sustainable future. The company remains committed to leveraging innovative technologies and solutions to solidify its role as a global leader in environmental responsibility.

HYOSUNG: Strengthening Core Capabilities to Address Environmental Challenges

HYOSUNG’s corporate philosophy of “Enhancing the value of human life” aligns seamlessly with the principles of sustainable management. To realize this vision, HYOSUNG launched the RE:GEN brand, reflecting its ambition to build a sustainable 100-year company through responsible management that contributes to a safer and more prosperous world.

At a company-wide level, HYOSUNG is devising core strategies to tackle environmental challenges. These efforts are supported by its R&D centers, including the Hyosung R&DB Labs, which has been instrumental in driving Korea's industrial progress. The center is actively developing new products and processes to reduce carbon emissions, ensuring these innovations translate into practical applications.

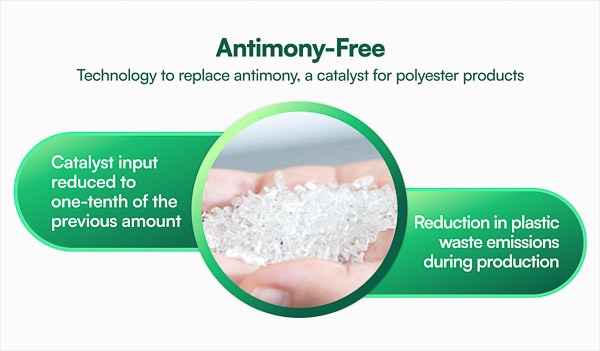

The Antimony-Free technology developed by the Hyosung R&DB Labs replaces antimony, a catalyst used in the production of polyester products. Antimony, one of the eight hazardous heavy metals, has long been a target for replacement by domestic and international companies. However, efforts to commercialize alternatives have largely failed. HYOSUNG began developing the tin (Sn)-based Antimony-Free catalyst in 2017, completing the technology and achieving mass production within just three years.

The Antimony-Free catalyst reduces catalyst input by one-tenth compared to conventional methods and cuts plastic waste emissions during polyester production by more than half. In recognition of this technological achievement, HYOSUNG was awarded the Grand Prize at the 2022 Korea Patent Technology Awards, receiving the prestigious King Sejong Award.

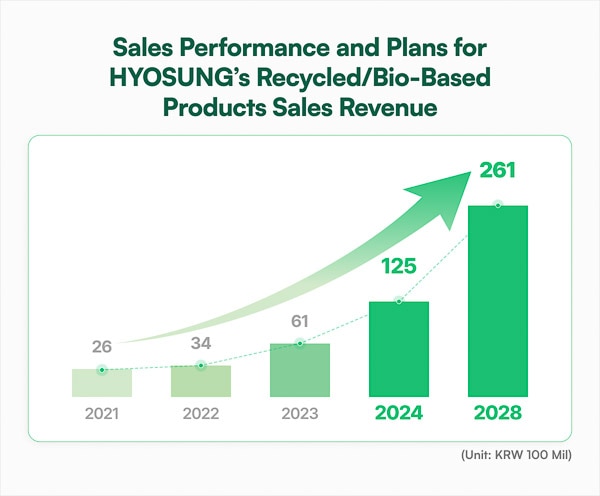

Hyosung is focused on producing products using recycled and bio-based materials, enhancing energy efficiency, and expanding research and development to contribute to the establishment of a hydrogen energy ecosystem. The company is actively pursuing various projects aimed at reducing carbon emissions through increased use of renewable energy sources and resource recycling. Additionally, HYOSUNG is investing in the development of technologies that target waste reduction and resource circulation, ensuring sustainable growth as a key driver of its business.

HS Hyosung Advanced Materials and Hyosung Chemical are paving the way for new opportunities with strategies and technologies that prioritize environmental sustainability. Beyond these efforts, HYOSUNG’s business divisions continue to pursue tailored research and development for each industry, promoting both environmental protection and industrial advancement. With these initiatives, the company strives to provide solutions for a better future. HYOSUNG will remain committed to fulfilling its environmental responsibilities and continue working toward a sustainable future as a leading global innovator in environmental technologies.