Content content

What do Google, Netflix, and Amazon have in common? These globally renowned companies share one key factor in their success: big data. As a core resource of the Fourth Industrial Revolution, where digital technology integrates into industries and daily life, big data is gaining increased prominence. Companies analyze data such as customer interests, consumption trends, and behavioral patterns to devise future strategies, direct marketing efforts, and make various critical decisions. For businesses, leveraging big data is no longer optional but essential for staying competitive and achieving sustainable growth.

Big Data Evolving with Technological Advances

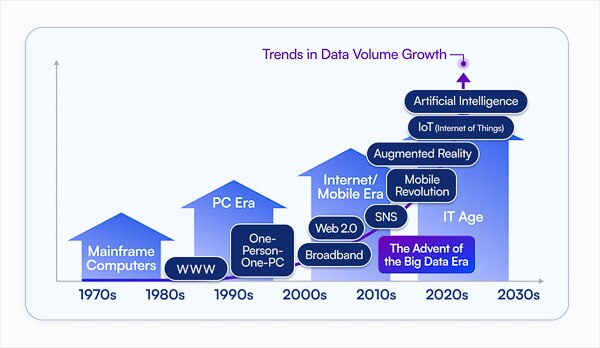

Big data refers to large-scale datasets generated in digital environments, encompassing numbers, text, and videos. As personal computers, the internet, and mobile devices became mainstream, the volume of data has grown exponentially to unfathomable levels. Everything from online shopping purchase histories to on-site navigation paths and wish lists, SNS uploads, and CCTV footage contributes to an ever-expanding digital footprint.

▲ Source: Kim Hyun-gon, Vision and Strategy for Advanced National Governance Based on Big Data (2012)

The history of big data dates back to the 1960s and 70s with the advent of computers. In the 1970s, as PCs and the internet began to be widely adopted, people started generating and sharing diverse information. By the 2000s, platforms like Google and Facebook allowed even more people to produce massive amounts of data.

From the 2010s onwards, mobile devices like smartphones and tablets enabled people to create data and share information anytime and anywhere. Around this time, the use of the term "big data" became more frequent, and its importance naturally came to the forefront. Today, technologies like IoT (Internet of Things), AI (Artificial Intelligence), and machine learning are further advancing the field.

Big Data in Action Across Various Sectors

How is the big data gathered from various channels being used in real life? The world's largest e-commerce company, Amazon, analyzed customer purchase histories, product searches, wish lists, and even mouse cursor dwell times to implement a "predictive shipping" system. Using algorithms based on big data analysis, Amazon sends likely purchased products to nearby distribution centers, so once a customer places an order, it can be shipped immediately. Amazon patented this predictive shipping system in 2014.

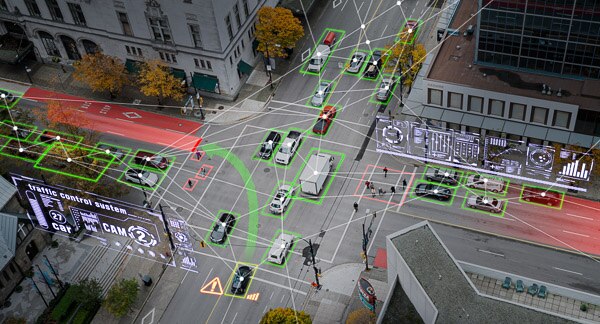

The global logistics company DHL used daily delivery data to understand the flow and patterns of logistics services. By analyzing optimal delivery routes in real-time based on recipient conditions, traffic, and geographical/environmental factors, DHL was able to bring delivery failure rates close to zero. Southwest Airlines analyzed consumer habits from a customer database of 96% of Americans and over 500 million people worldwide to provide personalized in-flight advertisements to passengers.

Like these examples, big data technology is being used across industries including logistics, transportation, finance, healthcare, and agriculture. It helps in developing new products by analyzing the correlation between the attributes of past and present products and their commercial outcomes. Additionally, it is used to predict maintenance needs based on production years, log items, and sensor data from industrial equipment. By analyzing factors like product production, sales, returns, and customer feedback, businesses can forecast demand and improve operational efficiency.

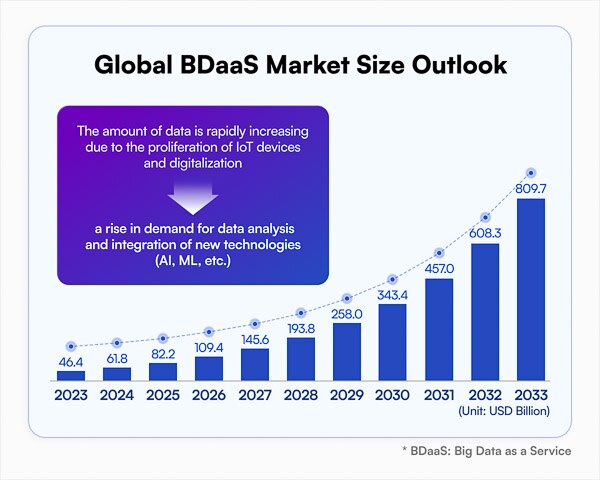

▲ Source: Market research firm Market.us

In particular, the manufacturing industry, which accounts for 25% of the national economy, is adopting smart factory systems using big data. To advance smart factories, data connectivity is essential. With connected data, manufacturing processes can be optimized, and key innovative technologies such as quality and supply chain management, predictive maintenance, and digital twins can be implemented. According to the "Results of Domestic Companies' Smart Factory Adoption" released by the Korea Institute for Industrial Economics & Trade (KIET) in June 2023, average productivity and revenue per company increased by 28.5% and 7.4%, respectively, while industrial accidents decreased by 6.2%, indicating enhanced manufacturing capacity.

HYOSUNG Leading Digital Transformation with Big Data

HYOSUNG is a global company, with exports accounting for 80% of its sales. To maintain consistent product quality and maximize production efficiency at its global manufacturing bases, the company has focused on establishing smart factories. By integrating information and communication technology (ICT) with core technologies, HYOSUNG has built a flexible and optimized production environment to keep pace with industrial changes.

▲ HYOSUNG’s smart factory system at the Vietnam plant

Since 2018, HYOSUNG has introduced smart factories at seven global spandex factories in China (Chuzhou), Vietnam (Dong Nai), Türkiye, and Brazil. The system collects and analyzes data on product conditions, equipment status, and more, from raw material import to product production and shipping, enabling monitoring of production status and detection of quality risks across the entire process.

HYOSUNG also utilizes big data to monitor customer needs and market conditions. Customer feedback from 34 manufacturing subsidiaries and 66 trading offices in 27 countries worldwide is being consolidated into a database to enhance competitiveness by responding to customer feedback and technical information. Additionally, customer relationship and experience management solutions have been added to the existing smart factory systems in heavy industry and textiles to segment customers and analyze buying patterns. This allows HYOSUNG to better predict customer preferences, leading to quicker proactive responses.

In Hyosung Chemical, real-time connections of all manufacturing resources and decision-making based on collected data have been implemented with the development of a Process Monitoring System (PMS), Quality Management System (QMS), and Visual Analytics System (VAS). These systems are praised for increasing productivity and reducing energy consumption, making them effective in addressing climate change.

▲ At ClickWorld Tour Korea 2023, focusing on artificial intelligence and data analysis, Hyosung ITX showcased its self-developed smart factory solution, ‘xtrmVAS.’

As emphasized by Chairman Cho Hyun-joon, HYOSUNG’s journey towards “data-driven management” continues. Since starting the smart factory business in 2017, Hyosung ITX has been collaborating with big data specialists to develop big data analysis solutions tailored to domestic manufacturing companies. These solutions are expected to create synergies across various manufacturing sectors such as construction, semiconductors, textiles, heavy industry, steel, and chemicals, helping HYOSUNG lead the digital transformation (DX) market. Meanwhile, Hyosung Heavy Industries has signed an industry-academia collaboration agreement with Pusan National University in August 2024 to advance its power facility asset management and preventive diagnostics business using big data analysis and AI algorithms. We look forward to seeing which new areas HYOSUNG will actively utilize big data to deliver innovative results in the future.