Milestones

many pioneering firsts and bests

in technological innovation.

With that foundation, we continue to grow

as leader to drive progress across textiles, chemicals,

heavy industries, and ICT.

The First · The Best · The First · The Best ·

The First · The Best · The First · The Best ·

-

2024

The First in Korea to Localize 200MW Voltage-Type HVDC Technology

In 2024, Hyosung Heavy Industries became the first in Korea

to localize 200MW voltage-type HVDC (High Voltage Direct Current)

technology using proprietary expertise. The system was installed

at the Yangju substation in Gyeonggi Province, where it now plays

a vital role in stabilizing the regional power grid.

-

2024

The First in the World to Commercialize a 100% Hydrogen Engine Generator

Hyosung Heavy Industries became the first in the world to commercialize

a hydrogen engine generator powered entirely by hydrogen.

As a next-generation, carbon-free power technology, it generates electricity using 100% hydrogen without emitting carbon during operation,

offering a powerful solution for reducing CO₂ emissions.

-

2022

The First in the World to Commercialize Bio-Based Spandex

The First in the World to Commercialize Bio-Based Spandex Hyosung was the first company to commercially introduce plant-based spandex made from industrial corn by replacing fossil fuel-derived materials with corn-based alternatives.

-

2022

The First in Korea to Commercialize LPIT and MU for Digital GIS

Hyosung became the first in Korea to commercialize Low Power Instrument Transformers (LPIT) and Merging Units (MU) for digital GIS systems.

Certified under IEC standards, this innovation helped reduce reliance

on imports through superior technical competitiveness.

-

2020

The First in the World to Develop a Digital Desk™ Solution

Hyosung TNS developed the world’s first Digital Desk™, a digital branch solution that is transforming banking operations by enabling automated in-branch services.

-

2017

The First in Korea to Commercialize an Asset Management System

Hyosung was the first in Korea to commercialize ARMOUR, an advanced asset management solution for substations. Designed to diagnose the condition of various substation facilities in real time, ARMOUR combines cutting-edge technologies such as AI and digital transformation (DX), offering an approach to power equipment management in the era of the Fourth Industrial Revolution.

-

2015

The First in Korea to Launch a Smart ATM Digital Kiosk

Hyosung introduced Korea’s first digital kiosk for banking services.

This non-face-to-face financial solution allows customers

to open new accounts and issue cards without visiting a bank branch.

-

2015

The First in the World to Commercialize Polyketone

POKETONE™ is a sustainable engineering plastic with excellent wear

and chemical resistance. As it is also non-toxic, its applications are expanding

into various sectors including children’s tableware, construction materials,

automotive parts, household goods, and leisure products.

-

2015

The First in Korea and Third in the World to Develop MMC-STATCOM

Since the late 1990s, Hyosung Heavy Industries has been researching

STATCOM technology. In 2006, it developed Korea’s first 345kV 100MVar

model. By 2015, it became the first in Korea and the third globally

to commercialize an MMC (Modular Multi-Level Converter) STATCOM,

applying the latest high-capacity, low-loss technology for grid stability.

-

2013

The First in Korea to Develop a Centrifugal Charging Pump

The centrifugal charging pump is a core component of nuclear power plants, used to regulate the recirculation flow and concentration of reactor coolant (borated water). Hyosung’s successful development of this pump marked

a significant advancement in Korea’s domestic nuclear technology.

-

2013

Recognized as a World-Class Product in GIS

Hyosung’s GIS (245kV and 420kV) was selected as a world-class product by the Ministry of Trade, Industry and Energy and KOTRA. Developed using proprietary technology, the GIS integrates disconnectors, arresters, and circuit breakers into a single compact unit, reducing installation space.

-

2010

The First to Reach No.1 in Global Spandex Market Share with Creora

Hyosung’s Creora spandex, Korea’s first domestically produced spandex, achieved the world’s top market share in 2010. Since its launch in 1992,

it has grown into an innovative global brand recognized for superior quality.

-

2009

The First in Korea to Receive International Certification for Gear-Type Wind Turbines

Hyosung’s 750kW gear-type wind turbine system, developed entirely

with domestic technology, became the first in Korea to be certified

by Germany’s DEWI-OCC, a global wind power certification body.

-

2009

The First in Korea to Build a TAC Film Plant

Hyosung independently developed TAC film technology and completed

Korea’s first TAC film production facility in Yongyeon, Ulsan.

TAC film is a key material used in LCD displays.

-

2007

The First in the World to Produce Yarn from Discarded Fishing Nets

This was the world’s first fiber created from recycled fishing nets.

-

2007

The First in Korea and Second in the World to Develop a 1,100kV GIS

Hyosung Heavy Industries was the first in Korea and second globally

to develop a 1,100kV GIS using proprietary technology, strengthening

its leadership in the ultra-high voltage power equipment field.

-

2001

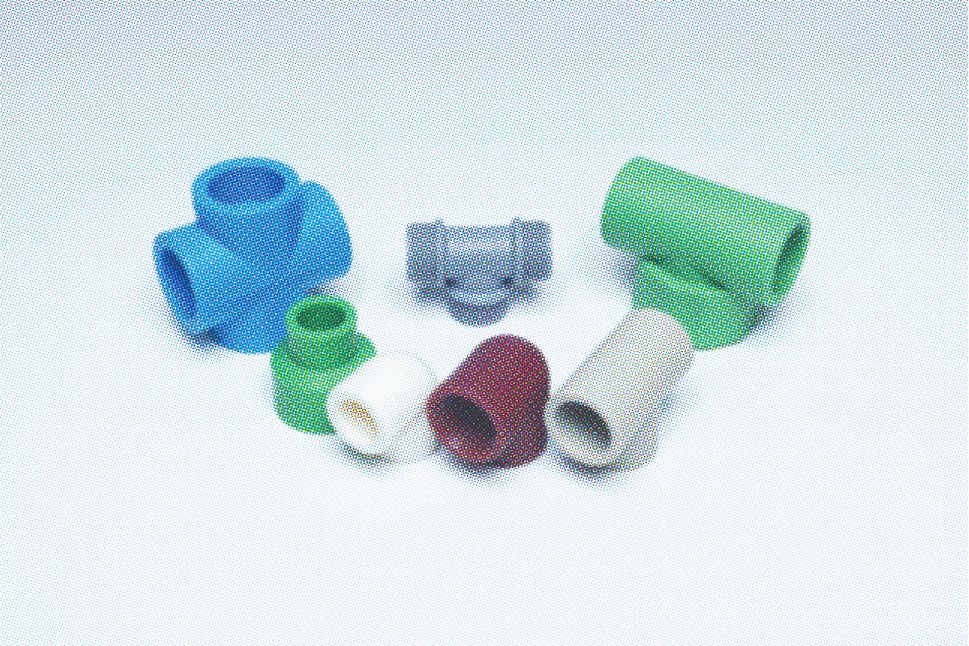

The First in Asia to Develop PP-R Pipes

Hyosung Chemical became the first in Asia to develop PP-R pipe products, an affordable, hygienic alternative to metal piping, recognized globally for their durability and long-term performance of over 50 years.

-

1998

The First in the World to Develop an 800kV 2-Break GIS

Hyosung Heavy Industries developed the world’s first 800kV 2-break gas-insulated switchgear (GIS), which has been recognized as technologically superior to the existing 4-break systems. It was a milestone that reinforced Hyosung’s global reputation in ultra-high voltage GIS.

-

1997

The First to Mass-Produce Spandex Production in Korea

In January 1997, Hyosung succeeded in the first-ever mass production of spandex in Korea. Through continued innovation, the Creora brand captured 30% of the global market, positioning Hyosung as the world’s leading spandex manufacturer.

-

1979

The First to Enter the Computer Industry in Korea

Hyosung was Korea’s first private firm to enter the computer industry.

A dedicated computer division was formed, engineers were sent to Hitachi

for training, and by 1980, a computer production plant was built in Gumi.

-

1971

The First to Establish a Corporate R&D Center in Korea

Hyosung established Korea’s first private corporate research institute in 1971. Originally focused on synthetic fibers that fueled industrial growth in the 1970s, the R&D Center later expanded into chemical materials and advanced technologies.

-

1969

The First to Develop a 154kV Power Transformer in Korea

In 1969, Hyosung Heavy Industries became the first in Korea to develop

a 154kV ultra-high-voltage transformer. In 1992, it went further to become

the first in Korea, and the sixth in the world, to develop a 765kV transformer,

ushering in a new era for Korea’s domestic power industry.