Content content

Climate change, air and water pollution, resource depletion, and waste management are complexly intertwined environmental issues. Addressing these challenges requires cooperation from governments, businesses, and citizens alike. HYOSUNG recognizes climate change and environmental issues as key societal priorities and continues to innovate to contribute to a better life for humanity and a sustainable future.

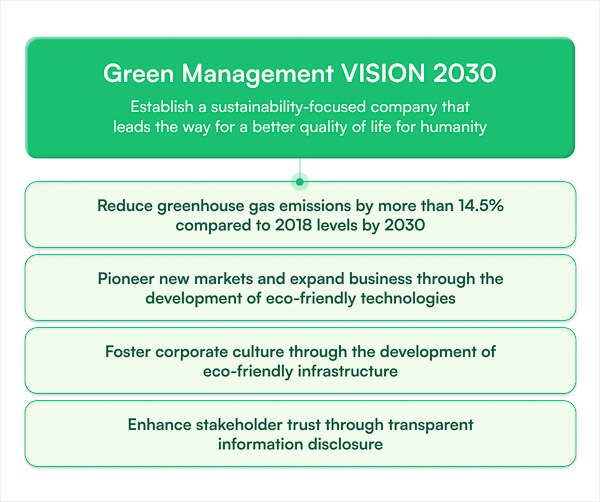

Under its "Green Management 2030" initiative, HYOSUNG systematically manages risks and opportunities related to climate change, placing sustainability at the core of its corporate culture. The company is proactively responding to global regulatory shifts, such as carbon emission regulations and plastic agreements, while focusing on developing new technologies and producing sustainable products. In alignment with the demands of environmentally conscious global customers, HYOSUNG strives to lead both the company and its customers towards a sustainable future. Beyond simply fulfilling its responsibilities towards environmental issues, HYOSUNG views these challenges as opportunities for growth, creating innovative products and services that drive future progress.

As part of these efforts, various subsidiaries of HYOSUNG are working in their own ways. First, let’s take a look at how Hyosung TNC and Hyosung Heavy Industries are addressing environmental concerns through their sustainable technologies and products. The following article will explore the innovations being achieved by Hyosung Advanced Materials and Hyosung Chemical.

Hyosung TNC - Fiber Innovation through Resource Recycling

Hyosung TNC is a global textile company that develops and produces spandex, nylon, and polyester yarns and fabrics. The company recognizes that the apparel industry has a significant impact on the environment, particularly due to the substantial role of raw materials. As the world's No.1 producer of spandex, Hyosung TNC is acutely aware of the need for sustainable raw material sourcing and places great importance on its responsibility in this area.

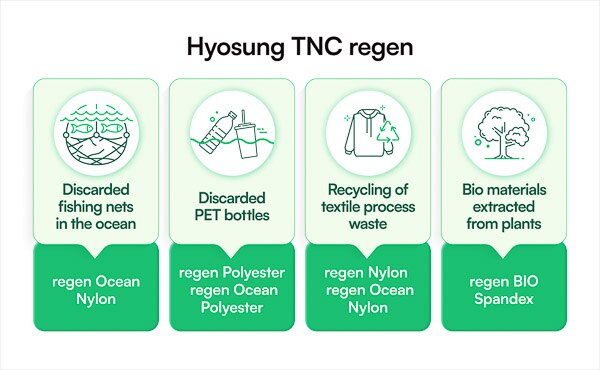

In the early 2000s, when there was limited demand for environmentally conscious products, Hyosung TNC pioneered the development of resource recycling technologies. It became the first company in the world to successfully develop recycled nylon yarn from discarded fishing nets and later produced high-quality yarns made from recycled PET bottles and industrial waste, leading the sustainable textile industry. Hyosung TNC also developed spandex made entirely from recycled waste yarn, transitioning synthetic fibers into sustainable products.

In addition to recycling technologies, Hyosung TNC has been developing fiber production technologies that utilize bio-based raw materials. By applying renewable bio-based materials extracted from plants in fiber production, the company is reducing the environmental impact compared to conventional synthetic fibers. Bio-based materials play a crucial role in sustainable fiber production.

Based on these technologies, Hyosung TNC introduced its exclusive sustainable fiber brand, regen. The regen brand uses recycled materials like PET bottles and discarded fishing nets or bio-based materials derived from plants, leading innovation in resource recycling and carbon reduction within the textile industry.

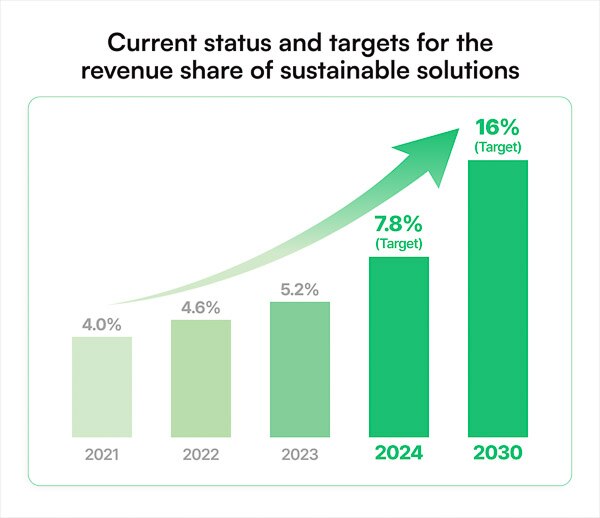

In this way, Hyosung TNC is committed to minimizing the environmental impact of the textile industry by developing sustainable products and technologies every year. The company has named its product lines based on EU Taxonomy, K-Taxonomy, and government eco-certifications as “sustainable solutions,” distinguishing them into the “regen” and “regen tech” categories. Hyosung TNC plans to gradually expand its sustainable solutions, aiming to increase their revenue share to 16% of total yarn product sales by 2030.

Hyosung TNC’s sustainable products have been validated through internationally recognized eco-certifications, reaffirming their reliability and quality. regen Polyester has received the Global Recycled Standard (GRS) certification for being a sustainable recycled fiber, while regen Spandex has obtained the Recycled Claim Standard (RCS) certification, verifying its excellence. The RCS certification is given to products containing over 5% recycled raw materials and ensures the continuity of recycled materials and product management. Additionally, regen Ocean Polyester has earned the Ocean Bound Plastic (OBP) certification, which verifies the collection, management, and recycling processes of plastic waste flowing into the ocean, contributing to addressing the marine plastic problem.

Hyosung Heavy Industries: Powering Innovation for New Energy Sources

Hyosung Heavy Industries, a global leader in industrial power systems and construction, is fully aware of the environmental impact of electric energy production and consumption. To address climate change, Hyosung Heavy Industries is expanding the production of next-generation power grid systems, offering essential solutions for a decarbonized economy and renewable energy transitions.

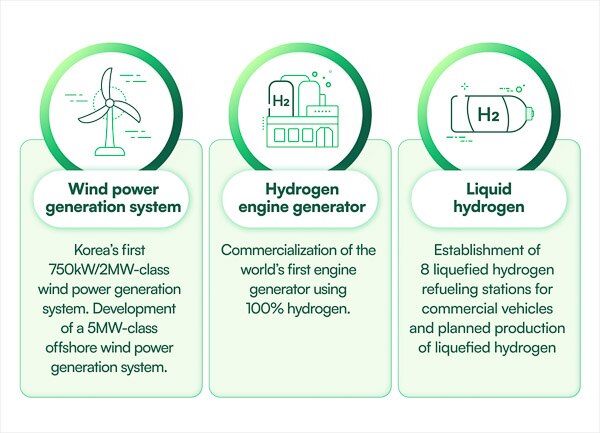

Wind power is a leading renewable energy source that harnesses the limitless resource of wind to generate electricity. Hyosung Heavy Industries is at the forefront of the domestic wind power industry, having developed the first 750kW and 2MW wind power systems in South Korea, as well as a 5MW offshore wind power system. This technological capability serves as a crucial steppingstone toward a sustainable future.

Hydrogen is another key element in future energy. Unlike fossil fuels, it produces no carbon emissions and has a high energy density, making it an economically attractive energy source. Hyosung Heavy Industries has achieved a significant milestone by commercializing the world's first hydrogen engine generator that operates on 100% hydrogen at its Hyosung Chemical Yongyeon Plant in 2024, enabling the production of power without carbon emissions. This accomplishment goes beyond mere technological advancement; it reflects a commitment to environmental responsibility.

Furthermore, Hyosung Heavy Industries is introducing ‘liquid hydrogen’ technology as a more efficient method for storing and transporting large quantities of hydrogen. This technology, which involves cooling hydrogen to create a liquid state, is essential for bulk transportation. Having established the first hydrogen fueling station in South Korea in 2009, Hyosung Heavy Industries has now become the No.1 company in the country for building gaseous hydrogen fueling stations and is currently setting up eight liquid hydrogen fueling stations for commercial vehicles. Additionally, the liquid hydrogen production company established in partnership with the global chemical giant Linde is set to begin production in the third quarter of 2024, playing a key role in the hydrogen economy.

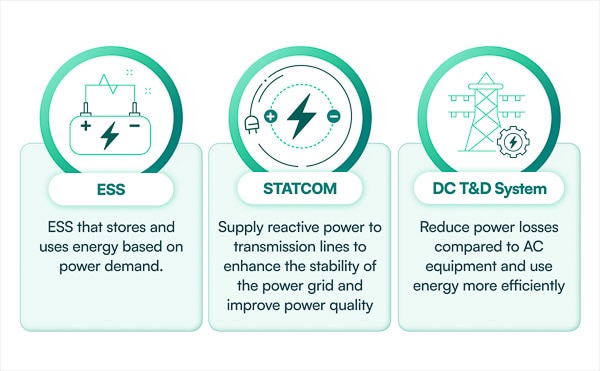

Renewable energy generation can be irregular due to factors like location and climate, making it crucial to store the produced energy. Hyosung Heavy Industries offers stabilization solutions for renewable energy power grids through Energy Storage Systems (ESS), which store energy during periods of low demand for later use, and STATCOM, which controls instability in power distribution networks and maximizes transmission capacity. In 2023, the company signed an ESS supply contract with the UK-based Verdant Bidco and is supplying STATCOM PJT to three countries in North America, demonstrating its global competitiveness.

How to efficiently transmit and distribute the stored energy is also important. Hyosung Heavy Industries has localized the Medium Voltage Direct Current (MVDC) transmission system, the first of its kind in South Korea for renewable energy. This system transmits medium-voltage electricity (1.5 to 100 kV) as direct current, reducing power losses compared to alternating current systems and allowing for more efficient energy utilization. Furthermore, the company has secured technology for direct current transmission systems across all voltage ranges, from low voltage (LV) to ultra-high voltage (HV), providing a comprehensive solution that can meet various energy demands.

Hyosung Heavy Industries is developing products and solutions that apply Clean Tech, providing essential innovations for the transition to renewable energy and the hydrogen economy. With proven global competitiveness in various sectors, including wind energy, hydrogen, and energy storage, Hyosung Heavy Industries will continue to present key solutions focused on environmental sustainability for the future.

Hyosung TNC and Hyosung Heavy Industries are preparing for the future through sustainable energy technologies and resource recycling in their respective fields of expertise. By innovating textile technologies and power infrastructure with an emphasis on environmental considerations, they strive to protect the environment while pursuing industrial growth. In the next article, we will explore how Hyosung Advanced Materials and Hyosung Chemical are creating a sustainable industry through progressive technologies.