Content content

Hyosung Heavy Industries Electro-Mechanical Solutions Part 2

Leading the Industry’s Future with Quality and Technology

The electro-mechanical industry has witnessed significant qualitative and quantitative growth, marked by key milestones like the invention of the steam engine and the discovery of electromagnetic induction. In Korea, the industry grew rapidly due to the economic development plans implemented in the 1970s. Hyosung Heavy Industries, which has been deeply invested in electro-mechanical business since the early 1960s, has played a pivotal role in localizing and advancing the technology in this field. Let’s take a closer look at what sets Hyosung Heavy Industries’ electro-mechanical solutions apart as they continue to thrive in the global market.

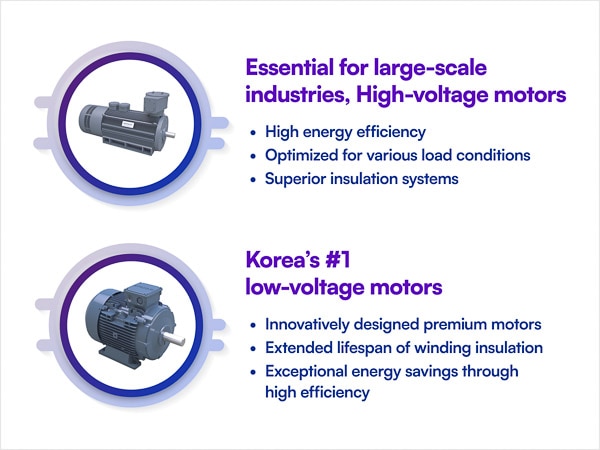

Dominating with Technology: The Heart of Industry—Korea’s #1 Electric Motors

Electric motors are devices that convert electrical energy into rotational kinetic energy. They are used in everything from household appliances like air conditioners and microwaves to the automotive and aerospace industries. In industrial settings like power plants, ships, steel production, petrochemical plants, and desalination plants, electric motors are indispensable, earning the title “the heart of industry.”

Hyosung Heavy Industries holds the top market share in Korea’s electric motor industry, particularly excelling in low-voltage motors with a commanding 40% share. The company’s monthly production capacity reaches around 40,000 units. For over half a century, Hyosung Heavy Industries has led the electric motor business, starting with its predecessor, Hanyoung Heavy Industries. In the past, Korea’s industrial sector relied heavily on imported electric motors. However, HYOSUNG turned the tide with the development of Korea’s first three-phase low-voltage induction motor in 1962, followed by the localization of products like the Brushless DC (BLDC) motor for defense use and the Q-Class motor for nuclear power plants.

Hyosung Heavy Industries’ products meet all the standards of KS (Korean Industrial Standards), IEC (International Electrotechnical Commission), NEMA (National Electrical Manufacturers Association), and GOST (Russia’s National Standardization Committee). The company offers a diverse range of motors, including high- and low-voltage, super premium efficiency, and explosion-proof motors. Hyosung’s high-voltage motors are widely used across various industries due to their superior insulation capabilities, low vibration, and noise reduction, resulting in a large and loyal customer base. Similarly, their low-voltage motors are distinguished by an advanced insulation system with excellent heat and moisture resistance and lightweight compact designs, making them ideal for a wide range of applications. Hyosung Heavy Industries also manufactures and supplies specialty motors such as DC motors and BLDC motors for cranes and presses, further expanding its influence both domestically and internationally.

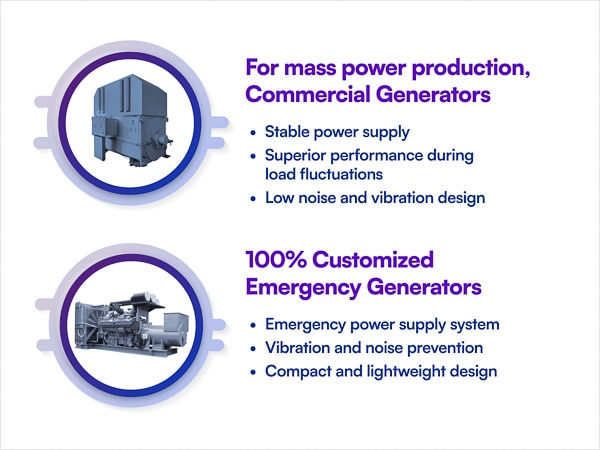

Sustainable Power for the Future: Renewable Energy Generators

Generators operate in reverse compared to electric motors, converting mechanical energy into electrical energy to supply power. Hyosung Heavy Industries has been developing and producing generators using its proprietary technology since the 1970s, demonstrating its capabilities through continuous R&D innovation. The company’s brushless design and advanced excitation system ensure stable power supply, while features such as Automatic Voltage Regulators (AVRs) and Permanent Magnet Generators (PMGs) offer exceptional performance during load fluctuations.

True to HYOSUNG's tradition of pioneering innovation, the company achieved significant breakthroughs in the generator sector as well. They were the first to localize the Motor & Generator-Set (MG-Set), a crucial component for controlling fuel rods in nuclear power plants. In May 2024, Hyosung Heavy Industries launched its first 100% hydrogen engine generator at the Ulsan Hyosung Chemical Yongyeon Plant 2. This generator, designed to use both hydrogen and natural gas, is expected to reduce CO2 emissions by nearly 7,000 tons annually. The company’s development of next-generation power products is regarded as a key innovation in line with the global push toward low-carbon technologies. ▲ HYOSUNG’s generators are divided into two types: for commercial use and for emergency use. Commercial generators are used in large-scale power generation facilities to produce power consistently and are deployed across industries like steel and petrochemical plants, as well as various industrial complexes.

HYOSUNG’s generators are utilized both domestically and internationally, with notable installations like the Korea Hydro & Nuclear Power’s Seomjin River Hydroelectric Power Plant (15,000 kW) and the Italy-based ALBA Project’s water turbine (2,064 kW). Emergency generators, on the other hand, provide power during outages or emergencies such as fires. These are typically installed in apartment complexes and public buildings. Hyosung Heavy Industries was the first in Korea to apply PMG systems to these generators, which significantly reduce vibration and noise. The company also miniaturized the medium-speed emergency generators and made it lightweight, allowing it to provide reliable power even in regions with limited energy access, such as Kuwait.

One-stop Customized Gear Solutions

Gears are used to transmit power from electric motors by adjusting rotational speed, torque, or direction. Hyosung Heavy Industries began producing gearboxes for the speed reduction sector in 1978, expanding its application to industries like petrochemical plants, steel production, and power generation. The company also localized gearboxes for ships, coal pulverizers for power plants, and high-speed gears.

Hyosung Heavy Industries’ competitiveness lies in its custom design capabilities across gearboxes, geared motors, and specialty gears. The gearboxes, containing a series of gears for transmitting power to the drive shaft, account for about 20% of the domestic market. HYOSUNG is now expanding into the global market, including the U.S., with its high-efficiency, low-noise, low-vibration, and high-specification gear solutions.

Hyosung Heavy Industries’ geared motors, combining electric motors and speed reducers, are designed with a strong focus on customer needs. By analyzing market demands, the company achieved high efficiency of 97%, along with noise reduction, weight reduction, and compact design. Their efforts in extending product lifespan and ensuring quick delivery have led to growing customer satisfaction.

Specialty gears, custom-designed for specific equipment, are produced for applications such as vertical roller mill gears, steel mill gears, and marine gears. HYOSUNG supplies high-speed gears for thermal power, steel, and marine industries and has been developing gears for wind turbines since 2005, further supporting the foundation for the green energy industry.

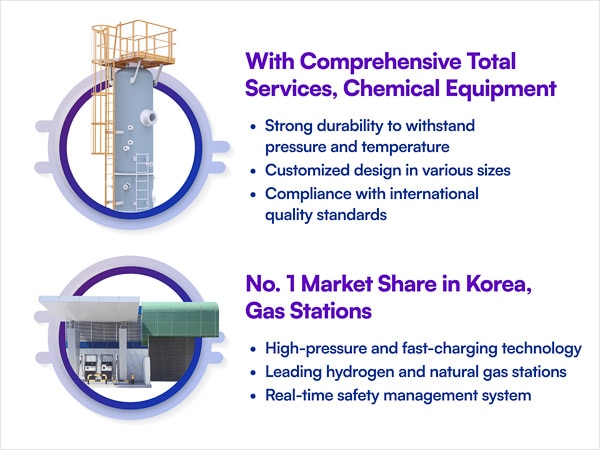

HYOSUNG’s Chemical Equipment Solutions Expanding Globally

Starting with electric motors, Hyosung Heavy Industries has expanded its business from generators and gears to chemical equipment. Chemical equipment is primarily used in pressure vessels for oil refineries, gas plants, and other processes. HYOSUNG offers a comprehensive service that includes the design, production, and delivery of chemical equipment that meets international ASME quality standards.

The company’s reactors, which store and process multiple substances, are known for their high quality and diverse range. Additionally, their meticulous customer service stands out, as they collaborate with prominent companies to provide detailed after-sales support and competitive pricing for their high-quality products.

Towers and columns are produced through a process that meets international standards such as ASME and PD5500, from design to manufacturing, inspection, and delivery. Hyosung Heavy Industries offers everything from standard tray-type towers to columns exceeding 100 meters in height. The company also manufactures various types of drums including heavy wall drums, which are capable of withstanding extreme temperatures and pressures. With its extensive experience in heavy industries, Hyosung Heavy Industries produces heat exchangers like coolers and condensers, earning trust in both domestic and international markets.

Hyosung Heavy Industries' chemical equipment has been supplied to major oil, gas, and petrochemical projects worldwide, especially receiving strong demand from North America, Asia, and the Middle East. Despite global uncertainties and prolonged austerity, infrastructure investments in key export markets are expected to continue. HYOSUNG plans to further strengthen its competitiveness through ongoing investment and effort.

Over the past two articles, we’ve explored the journey of Hyosung Heavy Industries in the electro-mechanical industry. Throughout this time, HYOSUNG has built unwavering trust by adhering to its principles of "quality, technology, and customer satisfaction" in both domestic and global industries. Now, the company aims to go beyond product supply and become a total energy solutions leader, fully committed to advancing industrial ecosystems and customer value. We invite you to keep an eye on the new era Hyosung Heavy Industries is set to usher in within the electro-mechanical sector.