Content content

South Korea's aerospace industry is entering a new era of growth, particularly marked by the establishment of the Korean Aerospace Administration (KASA) on May 27, 2024, which is often referred to as the Korean equivalent of NASA. The government has ambitious plans to increase its space development budget to over KRW 1.5 trillion by 2027 and plans to invest more than KRW 30 trillion in the next five years, with aerospace technology being selected as one of the country's ‘12 key national strategic technologies.’ Amid this expansion, HS Hyosung Advanced Materials' carbon fiber technology is making significant contributions to the aerospace sector.

An Unyielding Challenge Towards the Aerospace Industry

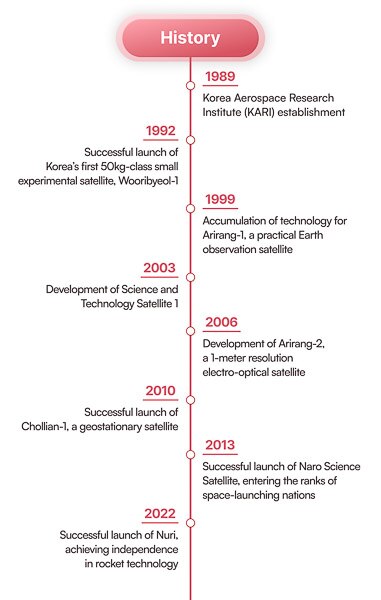

South Korea’s aerospace technology has steadily grown since the establishment of the Korea Aerospace Research Institute (KARI) in 1989. The country laid the foundation for space development in earnest with the successful launch of its first small satellite, "Wooribyeol 1," in 1992. In 1999, the launch of "Arirang 1," Korea’s first multi-purpose satellite, enabled the nation to accumulate earth observation satellite technology, while also establishing a foundation for launch vehicle technology through the development of small and medium-sized scientific rockets. The 2000s saw significant advancements in satellite technology with the development of practical satellites such as "Arirang 2" and the geostationary satellite "Chollian 1."

The development of launch vehicles began in earnest in the late 2000s. In 2013, after several launch failures, the "Naro" (KSLV-I) successfully placed a scientific satellite into orbit, marking Korea's entry into the ranks of spacefaring nations. Following this, the "Nuri" (KSLV-2), developed with domestic technology, achieved a successful launch, realizing a historic milestone in rocket technology self-reliance. In 2022, Korea’s first lunar orbiter, "Danuri," was successfully launched, furthering the nation's lunar exploration plans. These foundations led to the establishment of the Korea Aerospace Administration (KASA) in 2024, as Korea sets its sights on national goals of a lunar landing by 2032 and Mars exploration by 2045. The country is striving to become one of the top five space powers and a global leader in the space economy.

Carbon Fiber: The Hero of the Aerospace Industry

One material that is indispensable to the aerospace industry is carbon fiber. Composed of fibers with over 92% carbon content, carbon fiber boasts high strength and lightweight characteristics, making it known as the "dream material" or the "cornerstone of future industries." HS Hyosung Advanced Materials leads the way in developing next-generation carbon fiber, making substantial yet often unseen contributions to the aerospace industry.

The aerospace industry’s reliance on HS Hyosung Advanced Materials’ carbon fiber technology is undeniable. The company's high-performance carbon fiber brand, TANSOME®, was the first material of its kind to be developed in South Korea using HYOSUNG’s proprietary technology. Each strand of carbon fiber consists of 12,000 fine filaments that are one-seventh the thickness of a human hair, and just six of these fibers can lift a medium-sized car. Despite being only a quarter the weight of steel, it is ten times stronger and seven times more elastic. Additionally, it has exceptional corrosion resistance, conductivity, and heat resistance, ensuring a long service life.

The name "TANSOME" is a fusion of "tanning," which refers to the burning process in carbon fiber manufacturing, and "Something Special," reflecting HYOSUNG’s commitment to creating new added value. True to its name, TANSOME is not only critical to the aerospace sector but is also utilized in various advanced industries, including hydrogen energy and defense, gaining recognition for its innovative technology in the global market.

HS Hyosung Advanced Materials' carbon fiber technology wasn’t developed overnight. The company began its carbon fiber development in 2008 and achieved its first successful development using only domestic technology in 2011. In 2013, it established a commercial production facility with an annual capacity of 2,000 tons, marking the start of significant commercialization. Subsequently, it obtained the IATF 16949 certification, meeting quality management system requirements for the automotive industry, and later secured the AS9100 certification for aerospace quality management systems, its high-performance technology and quality being globally recognized as essential to the aerospace industry.

TANSOME: Leading the Future of the Aerospace Industry

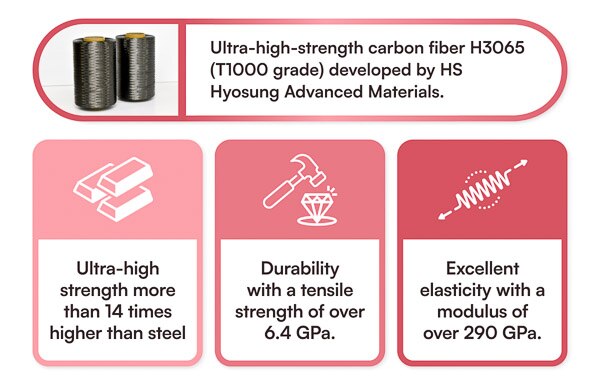

In 2022, HS Hyosung Advanced Materials developed the H3065 (T1000-grade) ultra-high-strength carbon fiber, which boasts significantly improved performance compared to the previously dominant H2550 (T700-grade) carbon fiber. This new material is 14 times stronger than steel and much lighter than traditional launch vehicle materials like aluminum. With a tensile strength exceeding 6.4 GPa, it is highly resistant to breaking, and its elasticity modulus surpasses 290 GPa, meaning it is incredibly resistant to deformation, even under external force.

This is where HS Hyosung Advanced Materials' ultra-high strength carbon fiber becomes the future of the aerospace industry. Materials to be used in the aerospace industry should withstand the vacuum and impacts encountered during launches, as well as extreme temperature fluctuations in space. By meeting these demands, carbon fiber plays a crucial role in reducing the overall weight of aircraft and spacecraft structures. This weight reduction translates into better fuel efficiency and lower operational costs.

HS Hyosung Advanced Materials is also developing an even higher-grade product with ultra-high strength (7.0 GPa) and high elasticity (over 380 GPa), which is expected to enter full-scale production by the end of this year. This new development will further enhance the company's competitiveness in the global market. In addition to expanding production in South Korea and China, HS Hyosung Advanced Materials has a roadmap to increase production in Vietnam. By 2028, the company plans to expand the global production capacity of its TANSOME brand to 24,000 tons per year, cementing its position as a leading player in the global market.

HS Hyosung Advanced Materials' Technological Independence

The development of T1000-grade carbon fiber by HS Hyosung Advanced Materials was a highly challenging achievement. Globally, this breakthrough places the company as the third to accomplish such a feat, following Japan and the United States, demonstrating its technological prowess on the world stage. This innovation carries even greater significance because it not only resulted in a new product but also achieved the localization of aerospace materials in South Korea. Previously, the country relied entirely on imported carbon fiber, but with this advancement, HYOSUNG made it possible to produce these materials domestically, enabling South Korea to become technologically self-reliant in this critical industry. By securing a stable supply chain for essential materials in the space sector, HYOSUNG has laid the foundation for Korea’s rise as a global leader in science and technology. Furthermore, HS Hyosung Advanced Materials' technological prowess has marked a crucial turning point, positioning South Korea as a leader in carbon fiber technology and paving the way for the country to establish itself as a global space power.

The aerospace industry represents the essence of ambition and challenge. HS Hyosung Advanced Materials' carbon fiber technology has become the backbone of this industry, forming the structural foundation for its continued development. As an essential partner to the aerospace sector, HYOSUNG will continue expanding its role through next-generation carbon fiber technologies, solidifying its position as a vital player in the future of aerospace.