Content content

With its leading products like CREORA in the spandex market and tire cords dominating nearly half of the global market, smart factories have become essential for HYOSUNG. To ensure the rapid production of consistently high-quality products anytime and anywhere, implementing smart factories was imperative. HYOSUNG has been steadily pursuing its smart factory business for several years, developing its own solutions to thrive in new markets. Here’s the story of how Hyosung ITX played a crucial role in the success of these smart factories.

The Birth of HYOSUNG’s Smart Factory Solution

In 2017, Hyosung ITX officially launched its smart factory business. To effectively manage the data that is central to smart factories, it was crucial to thoroughly identify specific details, issues, risks, and requirements during the manufacturing processes. Consequently, Hyosung ITX began by conducting on-site assessments at each factory and designed an optimized roadmap based on the findings. This was followed by the development of systems for collecting, managing, analyzing, and monitoring standardized data, along with the implementation of automated process control systems, laying a solid foundation for the initiative.

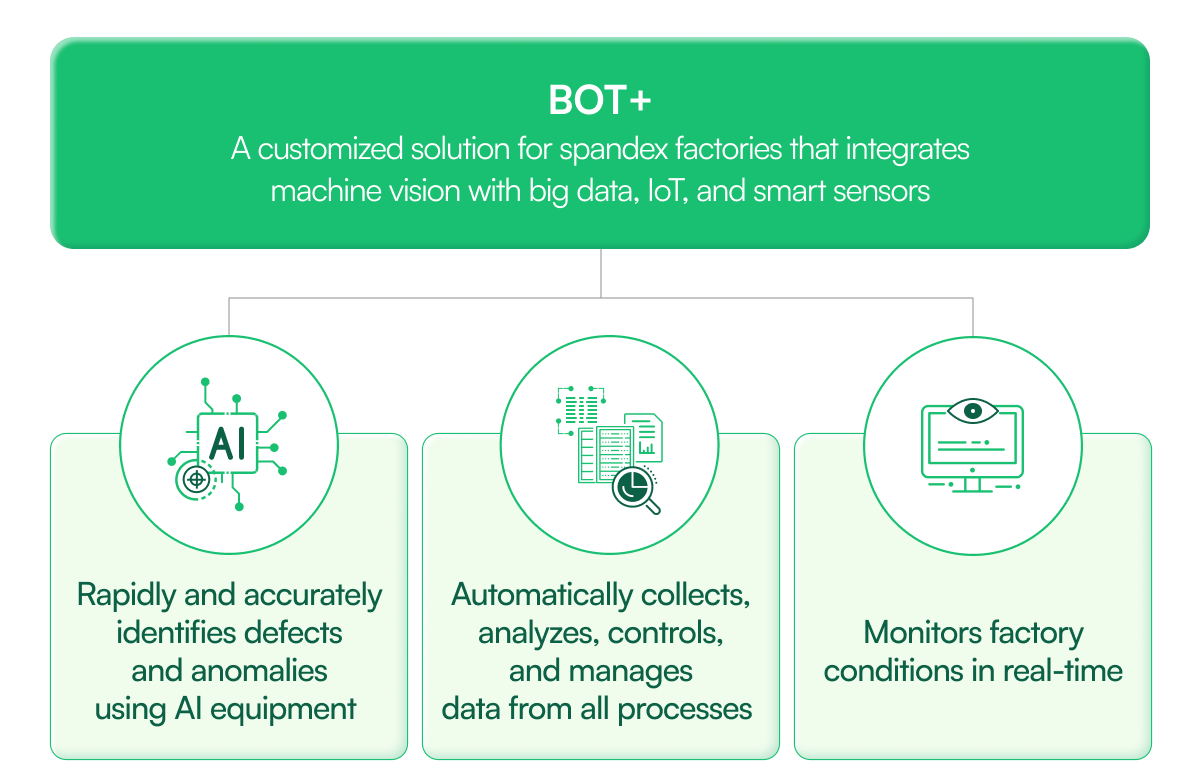

Through these efforts, Hyosung ITX has developed its smart factory system, BOT+. BOT+ is a customized solution for spandex factories that integrates machine vision with big data, IoT, and smart sensors. An AI system capable of analyzing product data captured by high-speed cameras allows for the quick and accurate detection of defects and anomalies. Additionally, BOT+ automatically collects, analyzes, controls, and manages data from all processes while providing real-time monitoring of factory conditions. This system has been successfully implemented in Hyosung TNC’s global spandex factories in China and Vietnam, establishing a global standard production system.

Growth and Innovation of Hyosung ITX Smart Factory Solutions

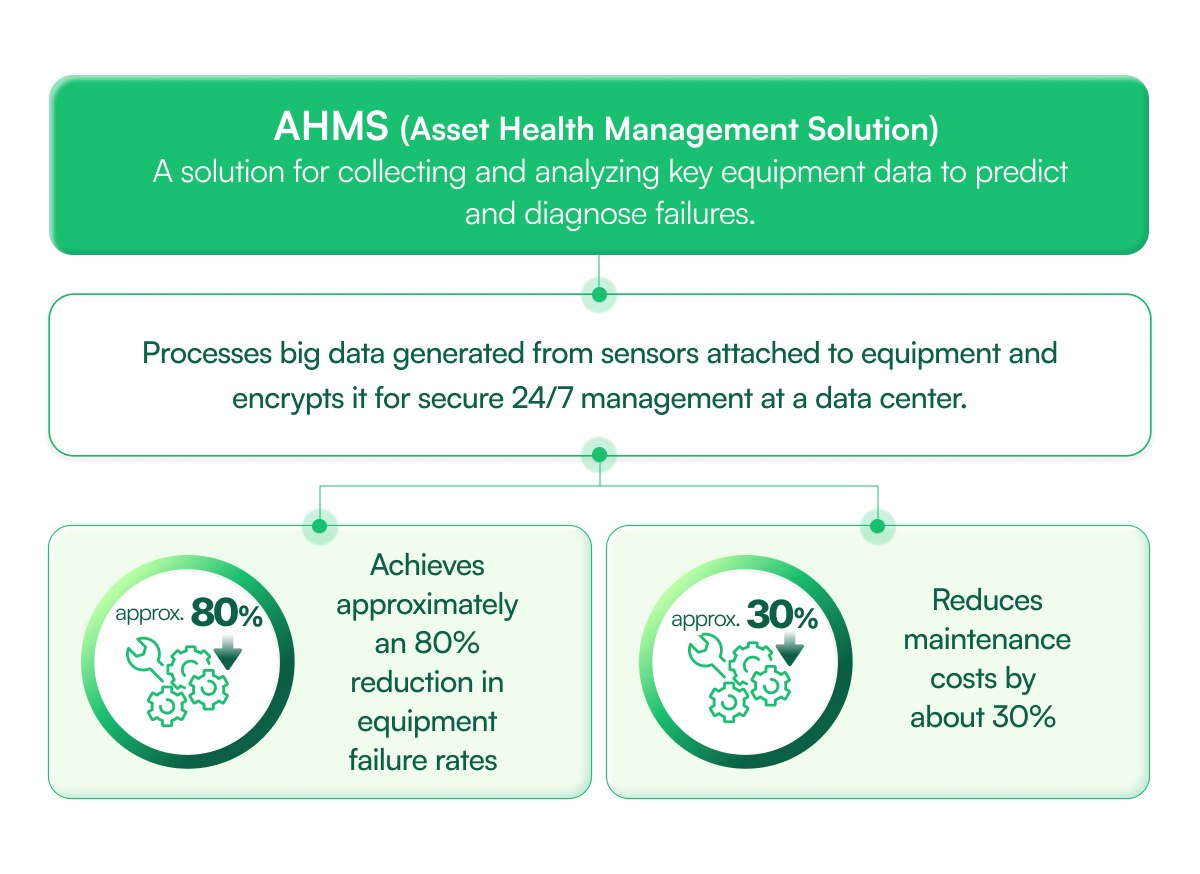

Hyosung ITX participated in the AHMS (Asset Health Management Solution) project initiated by Hyosung Heavy Industries in 2017, developing a big data analysis platform. AHMS is designed to collect and analyze key equipment data to predict and diagnose potential failures, successfully utilizing 35 years of accumulated data from substations. The big data generated from sensors attached to the primary equipment of AHMS is processed and encrypted for secure management at a data center 24/7. The introduction of AHMS has led to an approximate 80% reduction in equipment failure rates and over a 30% decrease in maintenance costs, significantly enhancing the maintenance efficiency of substation facilities.

Building on the success of BOT+ and the AHMS project, Hyosung ITX recognized the potential for new business opportunities and proactively embarked on developing additional solutions. In 2018, they launched the intelligent smart factory solution ‘XTRM FACTORY,’ and in 2020, they collaborated with SAP Korea to develop a ‘Smart Factory Solution’ with enhanced predictive capabilities, establishing a more systematic business model.

Currently, more than 20 global production bases within HYOSUNG affiliates utilize Hyosung ITX’s smart factory technology, ensuring stable production levels. Notably, Hyosung Chemical has transitioned all its facilities into smart factories, maximizing both production and energy efficiency.

The Key to an Outstanding Smart Factory Solution

Smart factories are categorized into five levels based on their utilization of ICT technology. At Level 1, data is simply collected and managed digitally, while at Level 5, the highest level, data from all processes is collected in real-time, with monitoring, control, and optimization being carried out automatically.

To build a superior smart factory, it's essential to actively integrate and utilize data-driven IoT technology. This is where Hyosung ITX's smart factory solution becomes a strategic choice. With decades of experience in the manufacturing industry and multiple global market-leading products, HYOSUNG has combined its accumulated know-how with cutting-edge ICT technology in its smart factory solutions, offering proven quality and effectiveness.

The greatest strength of Hyosung ITX’s smart factory solution lies in its customized services. It delivers solutions optimized to each client’s operational environment, helping companies differentiate themselves in domestic and international markets. Real-time production data is collected and analyzed, with various factors such as industry type, equipment condition, working environment, and process flow being considered to propose optimal smart factory solutions. In addition, an environment is created where ICT technologies can be seamlessly utilized, and essential information is provided for production planning and decision-making, ensuring a stable operational foundation.

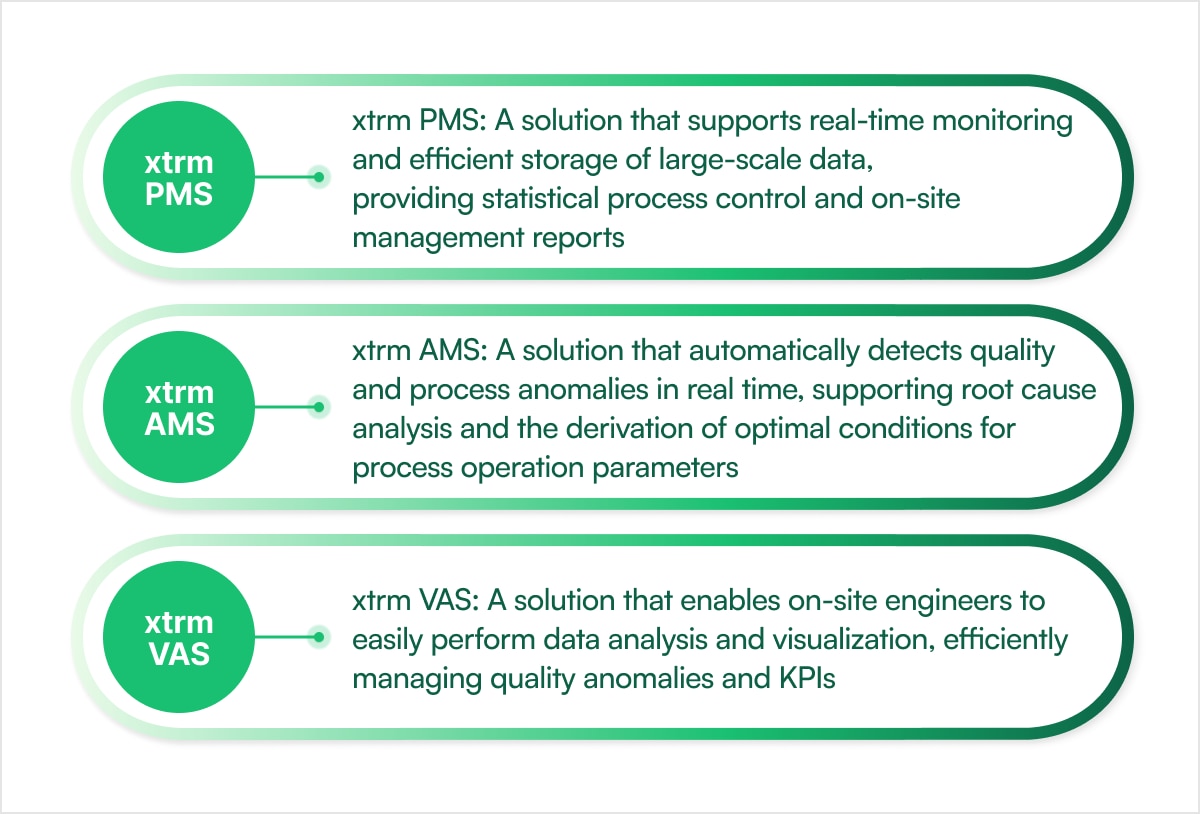

HYOSUNG’s tailored services are centered around its smart factory solutions, which include the DI (Data Integration) platform construction and operation, the DA (Data Analytics) platform for process optimization consulting, and BI (Business Intelligence) software. Key solutions include xtrmPMS, xtrmAMS, and xtrmVAS. xtrmPMS is a technology that supports real-time on-site monitoring and the efficient storage and utilization of data. Through various reports, it allows for a quick overview of the field’s flow and specific points, enabling fast responses to on-site situations. Additionally, xtrmAMS, which fosters a safe working environment, automatically detects quality and process anomalies in real time. It is highly beneficial in preventing accidents, dealing with unexpected situations, and assisting in the establishment of preventive management plans.

The DA platform xtrmVAS, an engineer-led analysis system, helps users easily access and visualize data through exploratory and visual resources. It simplifies complex process data so that even non-experts can understand it, improving communication among workers and allowing for swift responses to process-related issues. xtrmVAS has been applied in HYOSUNG’s global spandex factories in countries like China, Vietnam, India, and Brazil, contributing to improving productivity and ensuring uniform quality. Its exceptional performance has been recognized externally, achieving a return on investment that is 30 times higher over a cumulative five-year period. HYOSUNG’s smart factory solution has already gained high trust in the market due to its proven results and technological prowess, and it will continue to lead with outstanding quality and innovation.

Differentiation through Digital Transformation and Big Data Solutions

Hyosung ITX is actively working on future new business investments and ecosystem development alongside its internal and external smart factory businesses. In 2023, HYOSUNG restructured its research and development organization into a Digital Transformation Headquarters, creating a separate team dedicated to smart factories to explore new business opportunities. The company is also actively collaborating with partners such as Kumho Tire and LS MnM to expand and enhance its business. In September 2023, HYOSUNG signed a memorandum of understanding (MOU) with data stream specialist DataStreams to activate the big data business ecosystem and contribute to the digital transformation of the manufacturing sector.

The MOU with DataStreams focuses on developing big data solutions tailored for domestic manufacturers. By integrating HYOSUNG’s smart factory solution, xtrmVAS, with DataStreams' big data fabric platform, ‘TeraONE,’ the two companies aim to create new solutions. xtrmVAS analyzes complex process data quickly and easily using AI and big data analytics, while TeraONE serves as a platform for storing and managing data swiftly and accurately. The fusion of these two technologies is expected to enhance accessibility and convenience regarding data.

There is a growing demand for the digital transformation of manufacturing from countries in the Global North like Germany and the United States, as well as in South Korea. If both companies succeed in developing manufacturing-specific big data solutions through this partnership, HYOSUNG will lead the digital transformation of domestic manufacturing in the smart factory sector and further strengthen its competitiveness.

According to market research firm Precedence Research, the global smart factory market is projected to grow to approximately KRW 370 trillion by 2030, more than 1.5 times its current size. For HYOSUNG, which has been tirelessly converting its production bases into smart factories and developing deployment solutions across all its subsidiaries, this presents a prime opportunity. Following spandex and tire cords, Hyosung ITX's smart factory solutions will continue to innovate to set new standards.