Content content

On January 2, 2024, at Tokyo International Airport, a collision occurred between a Japan Airlines (JAL) passenger plane and a Japanese Maritime Safety Agency transport plane. The aftermath of the accident resulted in the loss of both aircraft, with five out of six crew members aboard the Maritime Safety Agency transport plane losing their lives. While it was one of the most devastating JAL aircraft accidents since the crash in 1985, miraculously, all passengers aboard the passenger plane were able to evacuate safely, preventing even greater loss of life. One of the contributing factors to this miraculous outcome is garnering attention: the carbon fiber reinforced plastics (CFRP)* used in the fuselage of the Japan Airlines passenger plane (Airbus A350 XWB).

*Carbon Fiber Reinforced Plastics (CFRP): A composite material composed of high-strength carbon fibers and plastic resin.

The Dream Material, Crafted by Hyosung

Carbon fiber is hailed as a lightweight yet highly durable and elastic material, often dubbed as the "dream material" and the "a key material for future industries." Carbon fiber is categorized based on its manufacturing method and raw materials. The mainstream types are PAN-based and Pitch-based, with PAN-based fibers occupying over 90% of the global market share. PAN-based fibers, derived from acrylonitrile, boast high strength and elasticity, enduring extreme environments, and are used in aerospace, sports equipment, automobiles, and more. On the other hand, Pitch-based fibers, derived from ‘Pitch,’ a residue from the petroleum or coal refining process, are advantageous in industries requiring high thermal and electrical conductivity.

Carbon fiber production is fiercely competitive among countries like Korea, Japan, Germany, and the United States. Until about a decade ago, Korea heavily relied on imported carbon fiber. However, the situation changed in 2011 when Hyosung Advanced Materials successfully developed domestic carbon fiber. Then, in 2023, Hyosung Advanced Materials' TANSOMEⓇ achieved significant growth, climbing to the 8th position in global market share. What is TANSOMEⓇ, and what innovations has it brought forth?

Leading the Carbon Fiber Industry from Korea, TANSOMEⓇ

Carbon fiber consists of fibers with over 92% carbon content. Despite being only a quarter of the weight of steel, it boasts over ten times the strength and seven times the elasticity. With superior heat resistance, corrosion resistance, conductivity, and sustainability, carbon fiber is highly sought after as a substitute for steel. It's considered a core material in various industries, from sports and leisure to renewable energy, aerospace, and space exploration.

As the future of this promising material unfolds, HYOSUNG is striving to secure its competitiveness. These efforts culminated in TANSOMEⓇ. TANSOMEⓇ, the first domestically developed carbon fiber in Korea and the third globally, is a carbon fiber brand introduced by Hyosung Advanced Materials in 2013.

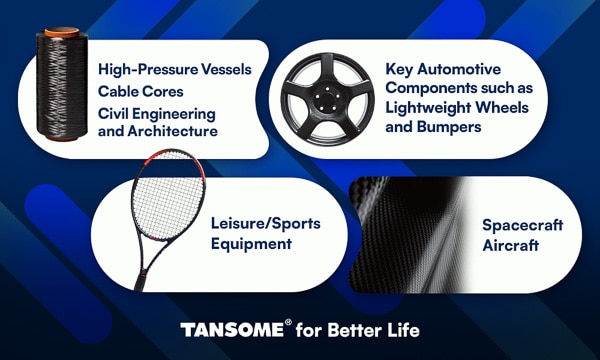

▲ TANSOMEⓇ product

Standard modulus carbon fiber, a versatile product, finds application in pressure vessels, conductor cores, structural reinforcements, and more. It offers safety, durability, and cost-effectiveness due to its lightweight nature, high strength, and corrosion resistance. Notably, pressure vessels are a major focus area for TANSOMEⓇ. Currently, it holds the top position in the compressed natural gas (CNG) high-pressure vessel market globally.

In everyday applications, carbon fiber is found in sports and leisure equipment like golf clubs, fishing rods, rackets, bicycles, and even archery bows and running shoes, owing to its lightweight, durability, and elasticity. Additionally, it serves as a critical material in aerospace structures, wind turbine blades, ships, and other applications requiring lightweight and high-strength materials.

Moreover, ultra-high-strength carbon fiber, with its exceptional tensile strength, is making waves in fields demanding even higher strength requirements, such as spacecraft. When applied to spacecraft, ultra-high-strength carbon fiber reduces weight, increases propulsion efficiency, and enables the transportation of more exploration equipment or crew members, thus proving to be economically advantageous. With its outstanding durability, heat, and vibration resistance, it garners even more attention in the era of space industrialization.

▲ Hyosung Advanced Materials' TANSOMEⓇ, a material that can be found everywhere in daily life. Source: Official Hyosung Advanced Materials YouTube Channel.

TANSOMEⓇ competes globally, boasting the same quality as leading companies in Japan, the United States, and Germany. Particularly, its ultra-high-strength products play a vital role in elevating Korea to the forefront of carbon material nations. In the past, ultra-high-strength carbon fiber, due to its complex production processes and technological challenges, was exclusively produced in Japan and the United States. However, with Hyosung Advanced Materials succeeding in domestic development in 2022, the path to domesticating advanced materials was opened. Hyosung Advanced Materials continues to strive for global competitiveness by advancing technology and expanding production facilities in China and Vietnam, ensuring the qualitative and quantitative growth of TANSOMEⓇ.

Embracing a Sustainable Tomorrow with TANSOMEⓇ

HYOSUNG’s focus on TANSOMEⓇ stems from the potential of carbon fiber, especially as its importance grows amidst the climate crisis. With the Intergovernmental Panel on Climate Change (IPCC) setting scenarios for achieving carbon neutrality by 2050, the future industries are actively responding. The government has announced plans to expand the adoption of electric vehicles to 4.2 million units and hydrogen vehicles to 300,000 units by 2030. Similarly, the aviation industry aims to achieve zero carbon emissions by 2050 through sustainable fuel conversion and aerodynamic light weighting. There are increasing anticipations in the role of carbon fiber in improving fuel efficiency and reducing carbon emissions.

TANSOMEⓇ sees these contemporary demands as opportunities to progress. With the global carbon fiber market expected to grow by around 15% annually, Hyosung Advanced Materials plans to expand TANSOMEⓇ production to 24,000 tons annually by 2028 to meet the ever-growing demand. Already, in 2013, Hyosung Advanced Materials established a factory in Jeonju, emerging as a leading company in the carbon material specialization zone in Jeollabuk-do. Upon completing overseas production line expansions, achieving the goal of being in the top three in the global market share is on the horizon.

Though starting as a latecomer, TANSOMEⓇ now stands on the brink of becoming a global top-tier player. Hyosung Advanced Materials will spare no effort or dedication until the goal of being a "Global Top Tier Player" becomes a reality. Stay tuned for the day when TANSOMEⓇ becomes the global No.1!