Contenido de contenido

As the world faced crises brought on by the COVID-19 pandemic and extreme weather events, the importance of taking real, practical action became evident. Consumers, increasingly aware of environmental pollution and climate change, are now turning their attention to products that contribute to protecting the planet. In response, businesses are seeking innovative solutions to tackle the climate crisis. Among them, HS Hyosung Advanced Materials has solidified its global #1 position by developing tirecords that improve automotive fuel efficiency. The company is advancing its ESG activities under the green management strategy of "Zero Waste," "Zero Emission," and "Zero Impact," and was recognized as a leading sustainable company in South Korea in 2023. Let’s take a closer look at the tirecord products that position HS Hyosung Advanced Materials at the forefront of the circular economy.

Tirecords that Lead the Industry with Exceptional Strength and Durability

While it may not be widely known, one of the essential automotive components is the tirecord, a fiber reinforcement material inside tires. Tirecords are critical for maintaining tire durability, absorbing the impact of driving, and providing a smooth ride. HS Hyosung Advanced Materials has been producing tirecords based on its chemical fiber technology since 1968. Today, about 48% of the world’s tires use HYOSUNG’s ‘PET Tirecords.’ As the global leader in this field for over 20 years, the company continues to invest in developing sustainable tirecords to reduce greenhouse gas emissions and water pollution.

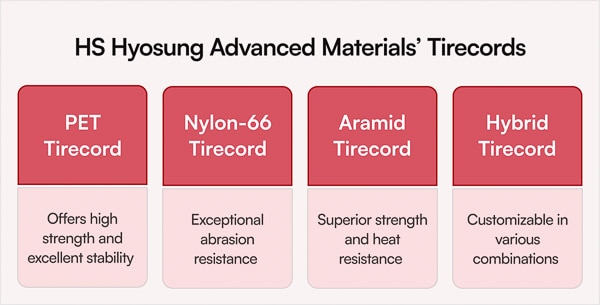

▲ HS Hyosung Advanced Materials’ Tirecords with High-Quality and Excellent Durability

HS Hyosung Advanced Materials’ PET tirecords are widely used in passenger and light truck tires due to their high strength, excellent dimensional stability, and superior adhesion. Nylon-66 tirecords, known for their outstanding abrasion resistance, are widely used in passenger cars, trucks, buses, and bias tires. With the growing demand for tires designed for electric vehicles and the need for enhanced tire performance, the demand for Aramid and Hybrid cords has also risen. HS Hyosung Advanced Materials is keeping pace with this market shift by developing and selling Aramid and Hybrid tirecords. The Aramid tirecord boasts five times the strength of steel and excellent heat resistance. Meanwhile, Hybrid tirecords can be customized using a combination of various materials to meet specific performance requirements, maximizing both efficiency and performance.

Transforming Waste into High-Performance Tirecords

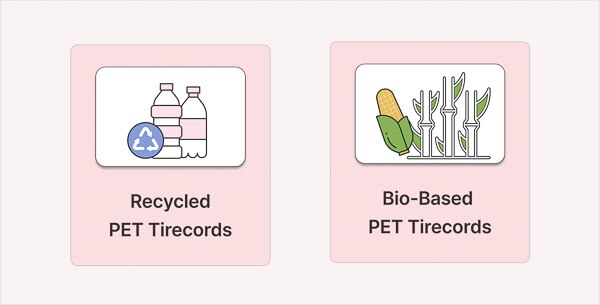

▲ Environmentally Conscious HS Hyosung Advanced Materials’ Tirecords

Since 2020, HS Hyosung Advanced Materials has been developing Recycled-PET tirecords using waste plastic bottles as part of its efforts to reduce carbon emissions. The company has now commercialized products using both mechanical recycling and chemical recycling processes. These recycled PET tirecords not only reduce the amount of PET bottles in landfills, helping to lessen environmental pollution, but also lower greenhouse gas emissions compared to conventional PET tirecords. Additionally, the company has developed Bio-Based PET tirecords, which use ethylene glycol derived from natural sources like sugarcane and corn. These bio-based products also contribute to reducing greenhouse gas emissions compared to traditional PET tirecords.

Some of the company’s products are designed from raw materials to manufacturing processes with environmental sustainability in mind. HS Hyosung Advanced Materials’ Lyocell Tirecord, developed using in-house technology, serve as a high-performance alternative to rayon tirecord and are primarily used in premium tires. Made from cellulose extracted from wood, Lyocell Tirecords are 100% biodegradable, and their manufacturing process generates fewer harmful substances like carbon disulfide and hydrogen sulfide, as well as less wastewater. Additionally, Lyocell Tirecords emit less greenhouse gas compared to traditional rayon or nylon cords, making them a popular choice among global tire manufacturers aiming to reduce carbon emissions.

Strengthening the Business Foundation and Targeting the EV Market

As automotive manufacturers increase their use of components that contribute to carbon reduction, there is growing interest in products with international environmental certifications. To meet this demand, domestic tirecord manufacturers, including HS Hyosung Advanced Materials, are reinforcing their tire reinforcement businesses through continuous investments and factory expansions. HS Hyosung Advanced Materials plans to invest around USD 10 million to expand its tirecord production line in Vietnam.

▲ iON, a tire for electric vehicles made from chemically recycled PET

The demand for tirecords is also rising with the growth of the electric vehicle (EV) market. EV tires, due to the weight of their batteries—around 400 kg—use 10-20% more tirecords than traditional tires. With the need for tires to support heavier loads, the demand for high-strength tire cords is expected to grow. HS Hyosung Advanced Materials is already supplying tire manufacturers with stronger and lighter tire cords, and it is actively developing dedicated products for EVs.

Global Certifications of HS Hyosung Advanced Materials: ISCC PLUS & FSC

ISCC PLUS is an international certification system for sustainable and low-carbon products that comply with the EU's Renewable Energy Directives (RED). It certifies products from raw materials to production process and distribution, ensuring global credibility and trust. HS Hyosung Advanced Materials became the first company in the tirecord industry to earn the ISCC PLUS certification, solidifying its leadership in sustainable materials and contributing to carbon reduction efforts. This certification covers tirecord production processes using raw materials such as 'Bio-based PET,' 'Mechanically Recycled PET,' and 'Chemically Recycled PET.' Achieving such global certifications is challenging due to strict criteria, but the company has successfully met these standards, significantly contributing to the advancement of the production of environmentally conscious products in the tire and related industries.

▲ HS Hyosung Advanced Materials tirecords with various certifications

HS Hyosung Advanced Materials is also developing Bio-based Nylon yarns and tirecords to meet diverse customer needs. After being the first in the world to commercialize Lyocell Tirecords in 2006, the company also became the first in the tirecord industry to receive FSC (Forest Stewardship Council®) certification. This international certification not only attests to the quality and competitiveness of Lyocell Tirecords but also highlights the company’s sustainable production processes and technological leadership.

Designing a Better Tomorrow with Natural Materials

HS Hyosung Advanced Materials' Green Flagship Brand Strategy is to focus on circular economy and carbon reduction based on the broader ESG strategy of the entire HYOSUNG brand, and to create synergies by securing ESG technology leadership based on substance. HYOSUNG, which has carbon-reducing technologies such as recycling and bio-based materials, uses natural materials through technological innovation and strives to bring the manufacturing and implementation of products closer to nature. The company is dedicated to continuing to lead the tirecord market with innovative technologies while thinking about the planet's tomorrow.