内容

The freshness of food is directly tied to ensuring a healthy diet. Naturally, packaging solutions that not only maintain freshness but also ensure safe storage have become increasingly important. It is now essential to apply packaging materials tailored to the characteristics of different food product categories. Hyosung Chemical is addressing this demand by developing high-performance food containers and packaging materials. From nylon films to PET films, the company offers customized solutions optimized for various needs. These materials ensure food safety, even at high temperatures, without concerns over harmful chemicals like endocrine disruptors. With its cutting-edge technology, Hyosung Chemical sets new standards for a healthier and safer eating experience.

Protecting Food Safety with Hyosung Chemical Products

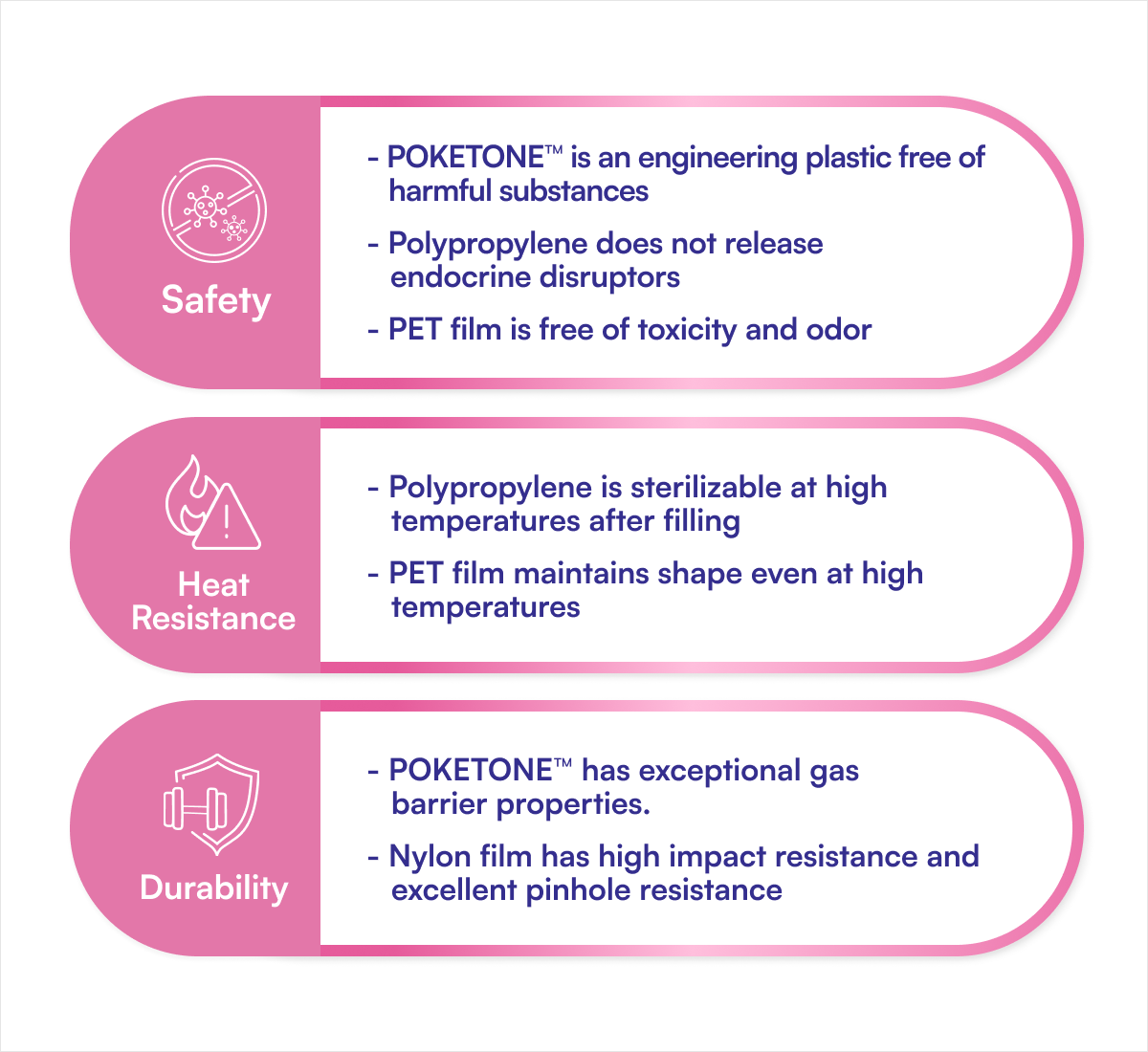

Hyosung Chemical’s packaging products are a common part of our daily lives. The reason these food products can now be safely packaged and preserved for extended periods is thanks to Hyosung Chemical’s cutting-edge technology, which ensures high levels of safety, heat resistance, and durability in their packaging materials.

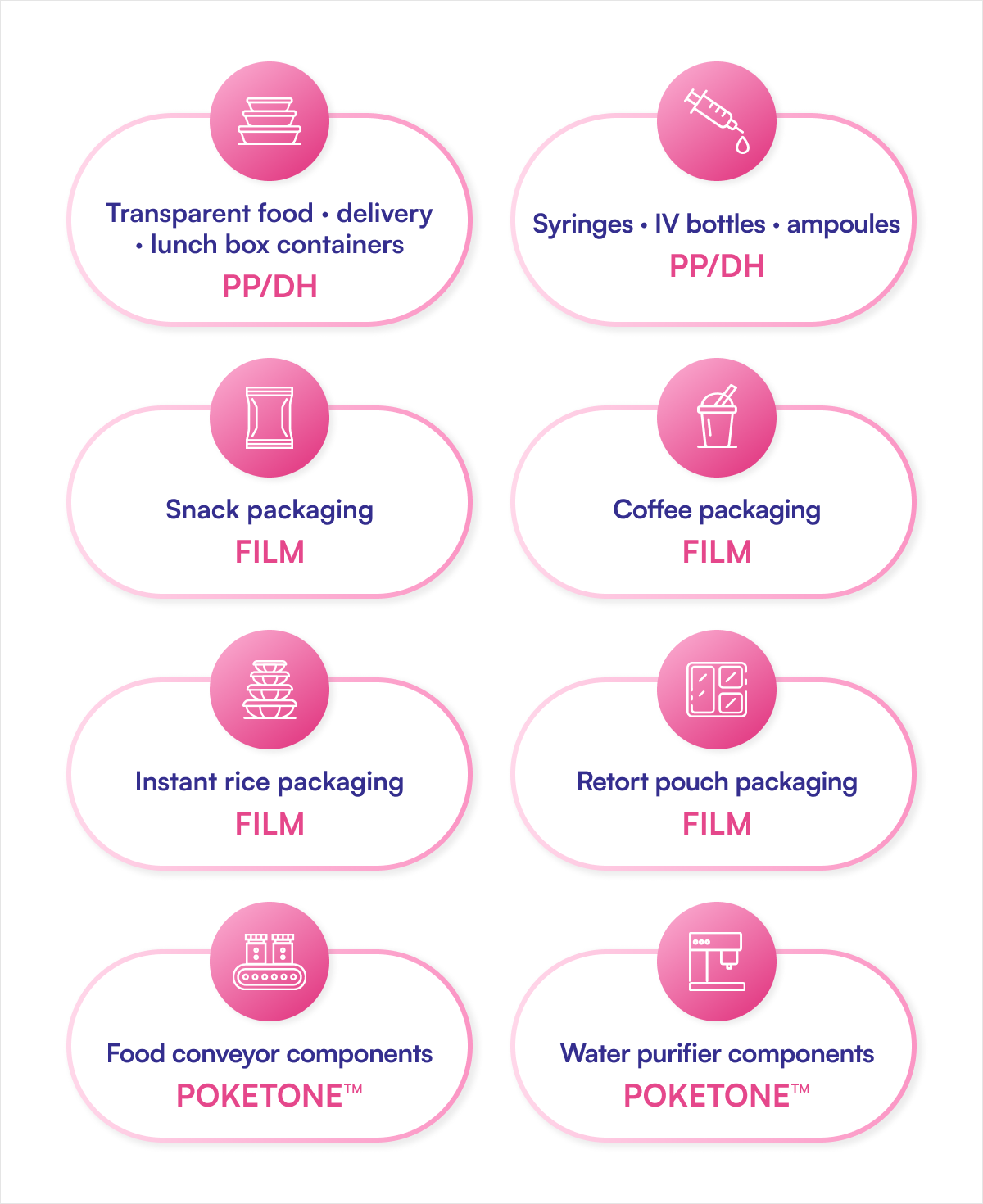

▲Key features of Hyosung Chemical’s safe packaging materials

When highlighting Hyosung Chemical's safe packaging materials, POKETONE™ naturally stands out as a key innovation. Hyosung Chemical developed this engineering plastic as the world’s first material free of harmful substances, ensuring safety in all applications that involve direct contact with food. As an sustainable material, POKETONE™ has been certified by both the FDA and Green Certification, offering superior protection to consumers' health during food storage and handling process. Its non-toxic properties and excellent gas barrier capabilities make it an ideal material for barrier films for food packaging, enhancing product freshness and longevity.

Additionally, Hyosung’s polypropylene (PP) is known for its superior heat resistance and durability. It is especially effective in the sterilization processes for retort products, preserving the taste of food while preventing the release of harmful endocrine disruptors.

Hyosung Chemical's nylon film is widely utilized in the food packaging industry due to its versatility and exceptional performance. It is custom-produced and supplied in various types, including general packaging, peelable film used in retort products and instant rice packaging, and pharmaceutical uses. Nylon film stands out for its resistance to external impacts and superior pinhole resistance, ensuring that it remains intact even under pressure. Additionally, its excellent oxygen barrier properties make it ideal for products requiring long-term preservation. Thanks to this high-quality technology, Hyosung Chemical's nylon film has secured the number one position in the domestic market and ranked third globally, leading the industry with its innovation and reliability.

PET film also boasts superior quality compared to conventional general-purpose films. It is non-toxic and odorless, and its air-blocking properties help maintain the freshness of food. It withstands high temperatures without deforming, making it suitable for food packaging that requires heat treatment. Additionally, it’s resistant to external impacts and abrasion, so it doesn’t tear or get damaged easily, allowing for long-term use. Because of these properties, PET film is widely used for various types of food packaging, including snacks, retort products, and sauces.

▲Hyosung Chemical’s membrane technology

Alongside this, membrane technology plays a crucial role in ensuring food safety. Membranes are used to purify the water used in food manufacturing processes. HYOSUNG’s membrane technology features high permeability and strength, consistently providing clean water across various water quality conditions. Based on its unique hollow fiber membrane technology, it effectively removes turbid contaminants and E. coli, allowing only highly purified water to pass through. This purified water is used not only in kitchen water purifiers but throughout the food manufacturing process to ensure the quality and safety of food products.

Everyday Moments with Hyosung Chemical Products

▲Product Range Made from Hyosung Chemical Materials

HYOSUNG’s products, responsible for food safety, are utilized in various food packaging materials in daily life. Polypropylene is widely used in food delivery containers and lunch boxes. Specifically, Hyosung Chemical's high-clarity PP Random Co-polymer is specially designed for balanced properties and excellent transparency, making it ideal for transparent food containers. This material is also used in the medical field, where medical-grade PP is utilized in syringes, IV bottles, and ampoules due to its outstanding transparency and biological stability.

Hyosung Chemical’s PET film is used in the snack packaging we commonly purchase. For such packaging, printability and adhesive properties are crucial, and PET film offers excellent print quality and reliable adhesion that lasts over time. Additionally, PET film is also used in coffee packaging, where it helps to block moisture and keep the coffee’s aroma and freshness intact for a longer period.

The secret to keeping instant rice fresh for a long time also lies in the packaging technology. To preserve food, it's crucial to block oxygen and maintain a vacuum, and nylon film does this in an excellent manner. Nylon film is used in the packaging of instant rice and cup noodles to block oxygen and create a vacuum, safely protecting the sterilized interior. Additionally, it’s suitable for packaging products that require high-temperature sterilization, such as retort pouches that can be heated with hot water or in a microwave and eaten right away.

Hyosung Chemical’s materials are used not only in food packaging but also throughout the food industry. Engineering plastics like POKETONE are used in various food processing equipment, such as conveyor components and water purifier parts. This material resists deformation or damage under the chemical and thermal conditions of food processing, offering excellent wear and impact resistance. It significantly extends the lifespan of equipment and helps reduce maintenance costs.

Hyosung Chemical’s Commitment to a Sustainable Future

Hyosung Chemical is actively working not only on developing functional materials but also on achieving a sustainable future. Polyketone, for example, has a low Global Warming Potential (GWP), significantly reducing carbon dioxide emissions. Its CO₂ emissions are only half those of other engineering plastics, so as demand for POKETONE™ increases, its environmental benefits will become even more pronounced. Membrane technology minimizes chemical usage and reduces energy consumption, contributing to water reuse and resource conservation. It is more energy-efficient than traditional thermal separation methods, making a significant contribution to environmental protection.

Hyosung Chemical meets the diverse needs of the food industry with high-performance materials, becoming deeply integrated into our daily food experiences. These innovative products ensure food safety and freshness, supporting a healthy lifestyle. Hyosung Chemical will continue to focus on sustainable material development, leading the way in making our tables safer and more abundant.